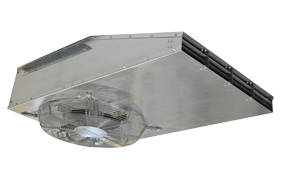

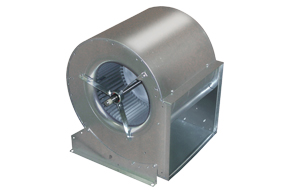

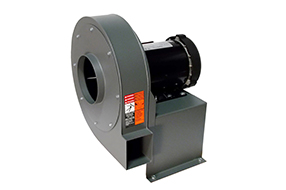

9200 Series Forward Curved Inline Duct Blowers

SKU#:

9200 SERIES

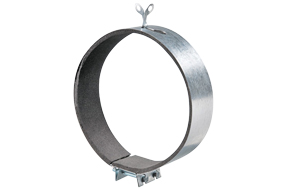

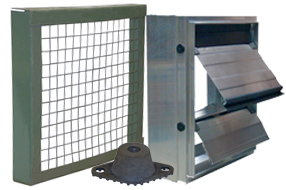

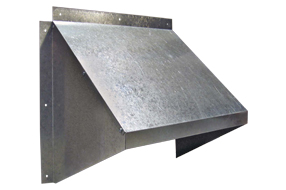

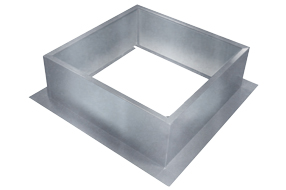

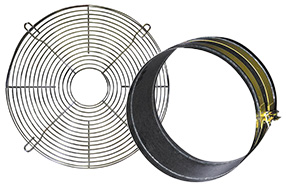

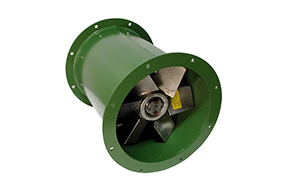

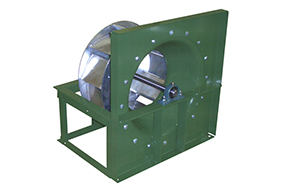

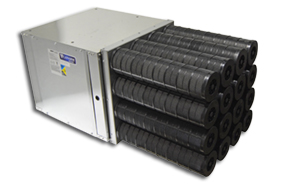

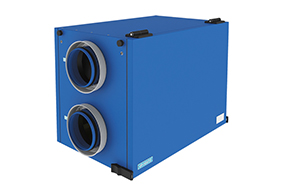

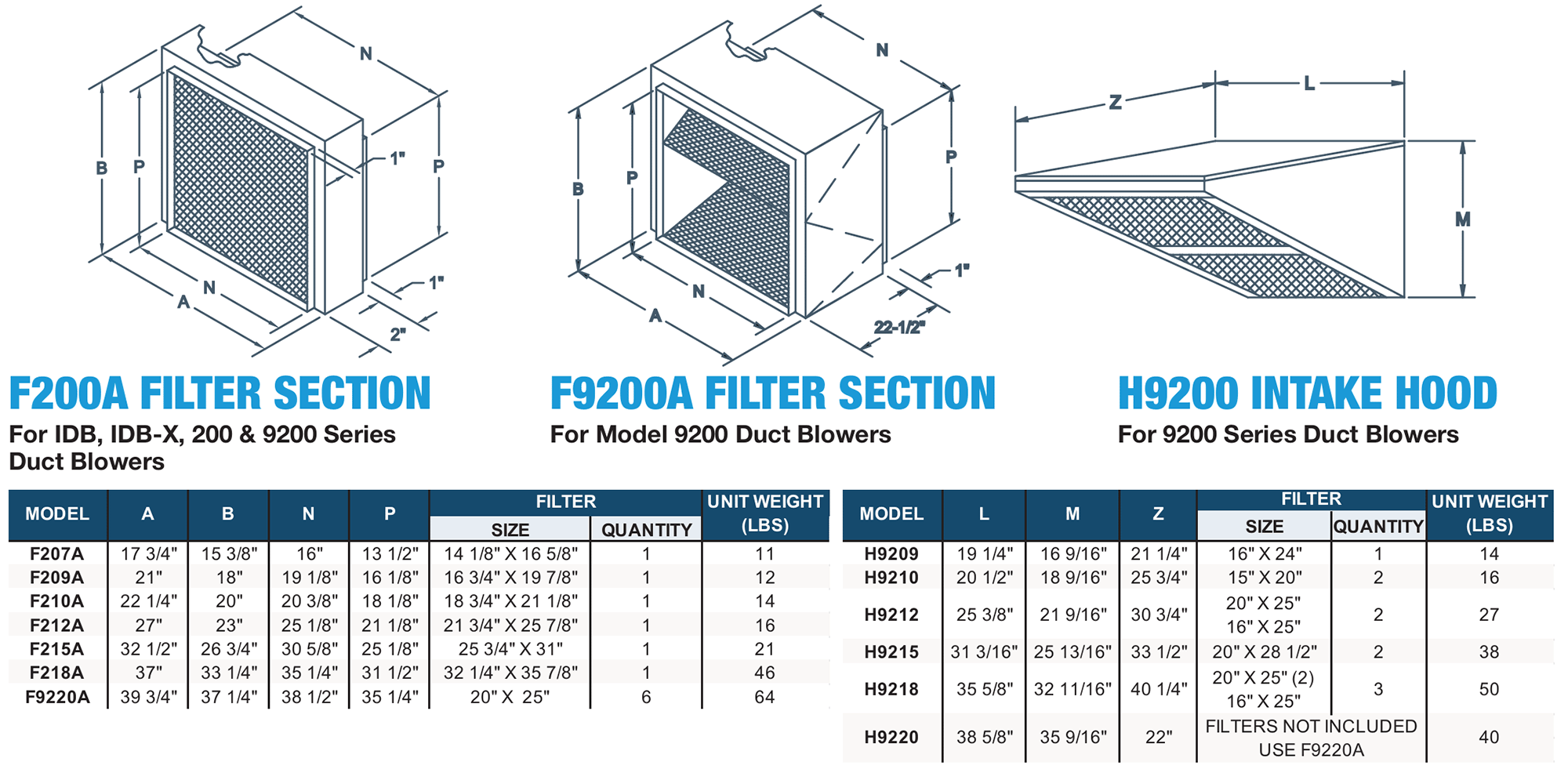

Model 9200 is a belt drive duct fan designed for interior/exterior supply, exhaust, make up air, or ducted return applications. Units feature forward-curved wheel, and powder coated housing. With accessory options such as filters, intake hoods and hot or chilled water coils for many different applications. Twin options available.