Natural Ventilation Design for your Dairy

Designing a natural ventilation system for your dairy involves putting together two necessary elements that create optimum conditions for yearround cow comfort. The basic design involves creating sidewall openings to allow adequate air movement throughout your barn in the spring, fall and summer, in addition to creating a ridge opening to facilitate proper minimum air exchange during winter conditions. For the purposes of this article, I will be referring to a dairy in a geographic area where four seasons exist; southern climates will have different parameters.

The required size of your sidewall opening will depend primarily on the width of the building being ventilated. The minimum design standard is 1 foot of sidewall opening on both walls for each 10 feet of building width. This opening size will vary depending on the structural wall height of the building and site considerations with regard to existing buildings and wind restrictions. In general, especially if you are planning on using a curtain sidewall system, the larger the opening the better. The curtain fabric when closed or partially open will provide you with the same protection as siding steel with the added benefit of extra air movement in hot weather.

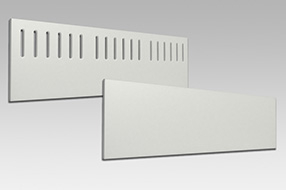

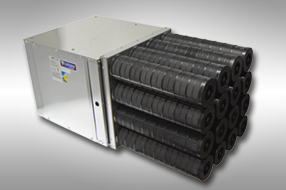

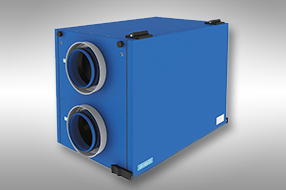

The ridge opening in a natural ventilation system is designed to provide draft-free exhaust of contaminated air in cold weather when the sidewall openings must be restricted due to colder outside temperatures. There are two basic types of ridge systems. The first is a continuous opening along the total length of the building, while the second is individual chimneys mounted along the building ridge. Both systems have different design calculations to confirm the size of opening and the size and quantity of chimneys required.

Once the basic design has been completed, you can then choose from the various systems that are available to operate on the sidewalls and the ridge. The main consideration when deciding on a sidewall system will be the desired interior operating temperature for your facility. There are different options available that will provide a variety of insulation values when closed that will allow for a range of functional inside temperatures. Economics should also be considered since some systems have longer potential life spans.

Wider freestall barns typically use curtain systems on the sidewalls that are available in many different operational styles. Narrower tiestall barns and calf barns are more suited for a sliding panel system that will typically seal tighter and have a higher insulation value than a curtain system. This allows for a warmer interior operating temperature, which is normally preferable in these applications. In both cases, operating your sidewall system with electric drive units that are activated on a temperature-controlled thermostat will allow the system to adjust the sidewall openings as required over a 24-hour period. This provides a more consistent temperature within the building, which is especially important during the spring and fall when exterior temperatures can change dramatically throughout the day.

If you choose a continuous opening for your ridge system, you may want to consider adding a cover system to allow air to escape from the building while preventing rain and snow from seeping in. With a chimney-style ridge exhaust system, you can have optional dampers within the chimney duct that can be adjusted to lower the air exchange and increase the interior temperature in cases of extreme cold. Care must be taken not to heat your barn up too much using this method, as you will trap the warm air that is full of humidity and ammonia in the building. This will lead to poor air quality and condensation on interior surfaces that can result in ice buildup.

In addition to the basic natural ventilation system, thought should also be given to whether any additional ventilation will be required for hot weather. Depending on your location, there may be a need to assist Mother Nature on days with high temperatures, high humidity and little or no breeze. One option is utilizing high-speed air for velocity cooling. Another is evaporative cooling using a sprinkler/misting system or moving air through a pad system with circulating water. Each of these has their own features and benefits, so it is important to review them all before deciding which system, if any, will best meet your needs from both a functional and economic point of view.

When designing your new dairy, proper care should be taken to ensure that the ventilation system you choose is capable of providing the necessary level of comfort for your animals that will maximize production and promote optimal herd health. As always, consulting a ventilation specialist in your area will give you the best chance for a successful outcome.

As seen in June 2023 edition of Progressive Dairy Canada.