Dual Ventilation: How does it work?

When designing a new dairy facility, there are a multitude of ventilation options available – both natural and powered. If you are planning a building with a ceiling and attic space, you should consider a system that will provide you with the best of both worlds.

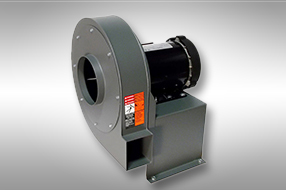

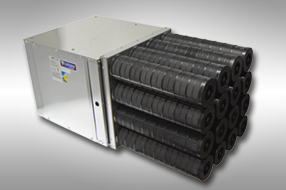

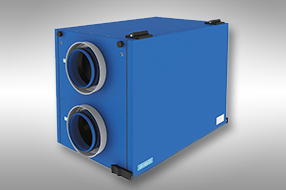

This system, commonly referred to as dual ventilation, uses fans in the ridge chimneys combined with fresh air intakes mounted in the ceiling.

It has been proven that large sidewall openings, controlled with either curtain or sliding panel systems, provide superior temperature control and environmental quality for the spring, summer and fall seasons each year in most areas of North America. The challenge has always been to provide the same level of control and air exchange in the winter months.

A standard natural ventilation system with properly designed ridge chimneys and interior temperature control can provide good-quality air throughout the winter, but dual ventilation can be used to take this quality to the next level.

Because the attic is a confined space and there will be heat transfer through the ceiling, the air in the attic will be warmer than the outside air. In cold weather, dual ventilation systems draw air from the attic through air intakes in the ceiling and direct it into the building along the ceiling line toward the outside walls. This air pattern causes the incoming air to slow down and pick up temperature from the interior air space before it moves through the livestock zone and is exhausted from the chimney fans, thus reducing the chances of creating a draft on your cows.

Chimney fans are typically operated on a variable-speed basis with multiple stages, depending on the size of the building. The chimneys and ceiling inlets are controlled so, as the temperature rises within the facility, the fans will speed up and the inlets will open a corresponding amount. By using this power portion of the ventilation system in the extreme cold, your sidewall curtains or panels will remain closed until the outside temperature is warm enough they can be opened without the risk of either freezing or introducing air into the facility that is considerably colder than the interior temperature. Since the fans used in these chimneys are operated with fractional horsepower motors, power usage is minimal.

Once the outside temperature has risen to an acceptable level, the ceiling inlets will be closed and the sidewall system will take over, providing you with all the historical benefits of natural ventilation.

As is now common with natural ventilation in dairy facilities, you can also add supplemental products to this system during hot weather. Typically, this involves the use of high-speed circulating fans, high-volume low-speed ceiling fans (HVLS) or tunnel ventilation.

In addition to the power ventilation equipment required for this system, you will also need an upgraded ventilation controller capable of operating chimney fans, ceiling inlets and sidewall openings all at once. This is especially important during those times of the year when the power system is operating overnight but the natural system is operating during the day.

Dual ventilation has been used in the swine industry for many years, so it is a tried-and-true system design that has proven to be extremely effective in the agricultural industry.

Be sure to meet with a supplier that has ventilation design experience to see if a dual ventilation system would be right for your dairy.

As seen in April 2022 edition of Progressive Dairy Canada.