Making winter ventilation work for you and your cows

As I’m writing this on a bright, sunny day in October with the temperature outside a pleasant 18°C, it pains me to realize the cold weather season is once again right around the corner. This drop in temperature during the winter months brings with it one of the greatest challenges of operating a naturally ventilated freestall dairy barn – maintaining a proper environment. In cold weather, it is imperative to have sufficient ventilation to remove humidity, ammonia and contaminants, while maintaining draft-free conditions and acceptable interior operating temperatures.

In a natural ventilation design, the ridge ventilation part of the system is used to create the minimum airflow required to keep air fresh. There are a number of different styles of ridge ventilation, but they all serve the same purpose – to exhaust a small volume of air from the structure, thereby allowing the introduction of fresh air into the environment. This fresh air intake is created by small openings in the sidewall ventilation along with infiltration air from outside.

The supply of heat is not an issue in a dairy facility because mature dairy cows are basically small furnaces generating heat 24 hours a day. The problem is that the heat produced is full of humidity and ammonia. If kept trapped inside, it will produce condensation that, in extreme cases, will actually create clouds of steam within the building. This condensation can also freeze and create ice build-up on the inside of the sidewall curtains or panels, which leads to potential hardware failure due to the increased weight.

The increase and decrease of cold weather air exchange in a natural ventilation system is achieved simply by adjusting the interior operating temperature. If you raise the desired temperature set point, the ventilation rate will lower to keep more heat in the structure by keeping the sidewalls closed. In a system where there are chimneys with baffles in the ridge, restricting the chimney openings will achieve the same result.

If you lower the temperature set point, the opposite will occur – the ventilation rate increases, introducing more fresh air while removing a larger amount of contaminated air from the interior.

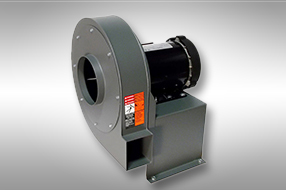

In addition to adjusting the ventilation rate, operations using high volume, low speed (HVLS) ceiling fans can be set to run at a very low speed (approximately 20% speed) in reverse to reclaim some heat. This moves a small volume of air upwards, which forces any heat that has stratified at the ceiling to be recirculated throughout the barn without creating a draft.

This brings us to the key point in this discussion: What is the best interior operating temperature in a freestall dairy barn in cold weather? Before we can determine this, there are still some variables to be considered. A freestall building that is designed with a fully insulated ceiling will be able to operate at a warmer temperature than a structure with no ceiling and minimal insulation under the roof steel. In general, when you walk into the barn in the morning and it feels cold, it is probably still too warm. In my experience, human nature is such that people will typically create an environment that they feel comfortable working in rather than what feels best for the cattle.

It is important to remember that a mature dairy cow will not start eating feed for the purpose of replacing body heat until the air temperature is below -5°C.

I have found that if you control your system to maintain an interior set point of 3 to 4°C in a fully insulated building, you can exchange enough air to maintain proper air quality without running into freezing issues with water and manure. In a building with minimal insulation, you may want to drop that set point to 1 or 2°C, which will keep everything working, as well as providing the cattle with better air to breathe. Over the years I have learned a quick and easy (if not extremely scientific way) to judge your winter ventilation rate. When you walk into the barn, you should smell feed before you smell manure. If you smell manure first, it means that the ammonia level is too high. This in turn means the humidity level is too high and your ventilation rate is too low. Lowering the temperature on your thermostat and letting fresh air in can easily resolve this. Your cows will be more comfortable and healthier. The rule of thumb is “cold and dry is better than warm and damp”.

So remember, the key to the successful operation of a natural ventilation system during the cold weather months is to keep your room temperature as low as possible to promote maximum air exchange given the outside conditions. Not only will your air quality be better, but you won’t have an inch of ice build-up on the inside of your ventilation curtains. You may need to improve the quality of your insulated coveralls, but your livestock will be happier and healthier.

As seen in Dec 2019 edition of Progressive Dairy Canada.